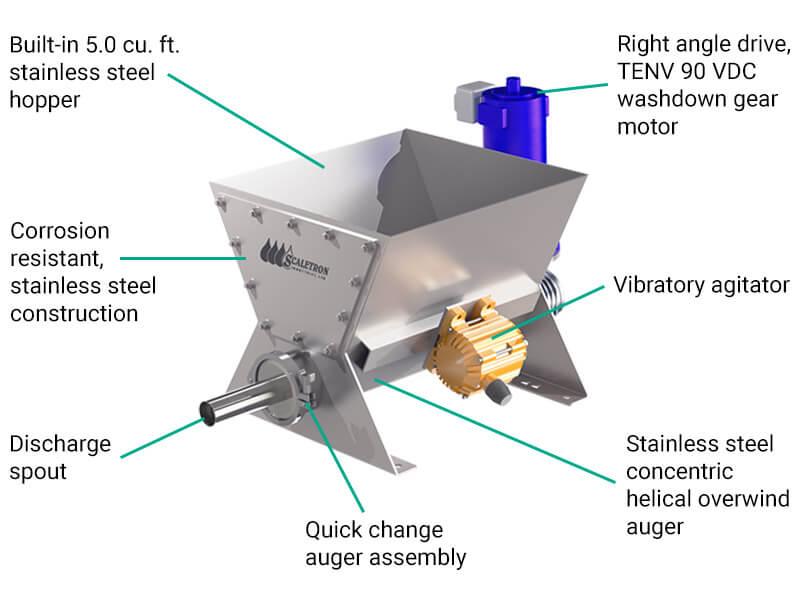

Scaletron’s VMF-90 Series Volumetric Screw Feeders are rugged, automatic metering screw feeders that are specifically designed for dispensing dry powdered or pelletized materials into a secondary process.

The VMF-90 Series feeders feature rugged construction – either stainless steel or carbon steel protected by a corrosion resistant finish. Augers and piping are all stainless steel.

The VMF-90 Series employ a right angle drive, variable speed, TENV 90 VDC washdown gear motor with a quick change auger assembly. To meet a range of application requirements, standard motors are available from 1/3 HP to 1.5 HP while optional Washguard® and explosion proof motors are available from 1/3 HP to 1.5 HP.

Quick change, concentric helical overwind feed screws are available in rugged 304 or 316 stainless steel as either a 3.75″ diameter solid auger or a 0.75″ to 1.5″ and 3.75″ diameter open helix auger.

VMF feeders are available with an integrated scale that allows measurement of dispensed amounts via “loss in weight” providing operators with constant real time assessment of the total mass of additive being used.

A number of control options are available to ensure accurate feed rates resulting 2% or better accuracy. From standard NEMA 4X SCR variable speed controls capable of remote installation to SCADA programmable motor controllers and HMI PLC touch screen interfaces for complete system control, the VMF-90 can be programmed to automatically adjust the feed rates of the material being added.

Efficient, time-saving material loading options can be added including:

Scaletron offers mixing tanks from 35 to 100 gallons and wetting cones to produce solutions or slurries by mixing dry chemicals, food additives and other materials with water.

Accessories for the VMF are designed to enable efficient and accurate processing of dry materials from powders to pellets and include:

Installation is a breeze as VMF systems are shipped fully configured for each specific application and ready to use. We stand by ready to assist our local distributor and you through the entire process.

At Scaletron, we are experts in providing solutions for the weighing and feeding of chemicals and other dry powdered materials. Our sales engineers and distributors have a wide range of experience in all types of applications and can help identify the right system to improve your operations.